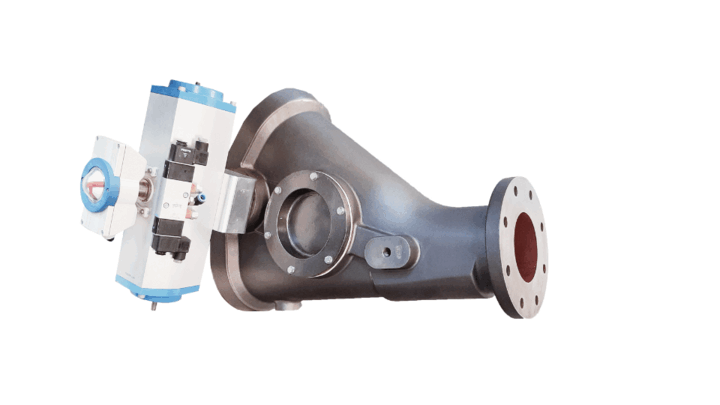

BTD ball type diverter

- For diverting or converging of extremely abrasive products

- Rugged design of ductile cast iron

- Suitable for high line pressures and temperatures

Introduction

The BTD ball type diverter valve is suitable for handling (extremely) abrasive products in heavy applications with relatively high line pressures and/or high temperatures.

The diverter is made of ductile cast iron. The rugged design ensures that the higher the pressure, the better the seal works. This is because the ball with the seal is pressed firmly into their seat. The seals can be replaced by removing the covers. This means that the BTD does not have to be dismantled and/or removed from the system.

The BTD is controlled by a double-acting pneumatic cylinder with a 5/2 double-acting solenoid valve and a position switch.

Applications

In brief

- Suitable for extremely abrasive products

- Suitable for high line pressures and/or temperatures

- Rugged design

- Body made from ductile cast iron

- Interchangeable wear bushings on the flanges

- Grease lubricated shaft seals

- Seals can be replaced without removing the diverter from the system

- ATEX 2014/34/EU certified (optional)

Specifications

- Flange dimensions: DIN65 up to DIN250 (7 sizes)

- System pressure: -0,5 up to 6 barg

- Standard product temperature: -10 °C t/m +150 °C

More info

Brochure Diverter Valves View