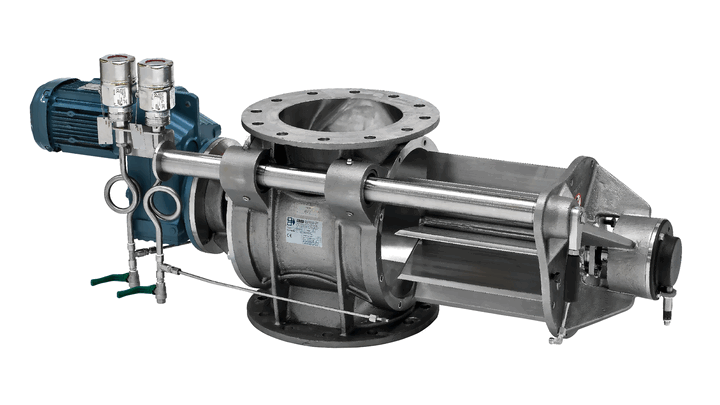

DG Quick-Clean valve

- High-duty rotary valve

- 24/7 industrial applications

- Frequent cleaning and inspection

- Protective system up to 10 barg (St1 and St2)

Introduction

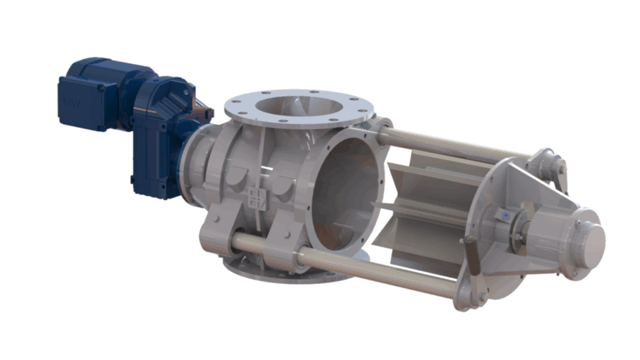

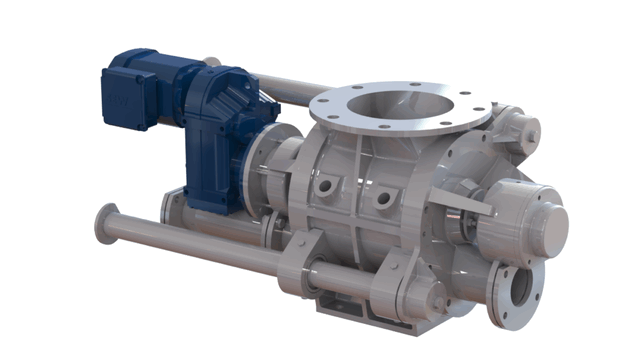

TBMA DG Quick-Clean rotary valves are specially designed for processes where frequent cleaning and inspection are required. The type DG valves are available in both drop-through (H-ARDG) as well as blow-through (H-GRDG) version.

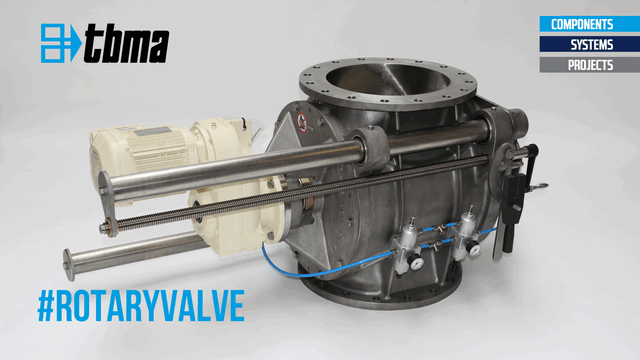

Easy inspection and cleaning | Due to the double-bearing construction, the rotor can be easily and safely removed and manually turned in pulled-out position. This way the rotary valve can be wet or dry-cleaned internally. The removed rotor can be turned and dry-cleaned. The guiding bars are long enough to give the operator ample access for inspection and cleaning of the inside of the valve.

Self-seeking shaft | The bearing construction guarantees a clearance-free run of the rotor and prevents damage when (dis)assembling. Contrary to valves of other brands, the TBMA Quick-Clean valves are equipped with a spline shaft. This means that after cleaning, the rotor can be quickly and easily mounted through the self-seeking shaft. The rotor adjustment is fixed and needs no readjustment after (dis)assembly.

Minimal chance of damage | Because of the clearance-free suspension and fixed adjustment, any metal contact of the rotor is practically impossible. Moreover, the chance of damaging the rotor tips and/or the inside of the valve during (dis)assembly is limited to a minimum. This is particularly important for hygienic applications. In addition, the shaft seal cannot be damaged, because the spindle with spline remains in place when the rotor is pulled out.

Applications

Spindle for optimal (dis)assembly

Early 2021, we assembled this DG350 drop-through rotary valve with extra spindle. The standard construction of our DG350 valve is extremely rugged: the bare shaft valve weighs 500 kg. Given the considerable weight of the rotor, we supply sizes larger than 300 with an extra spindle for optimal safe and smooth (dis)assembly.

TBMA DG Quick-Clean drop-through and blow-through rotary valves are specially designed for processes where frequent cleaning and inspection are required. The self-seeking spline shaft allows quick and easy remounting of the rotor after cleaning. Thanks to the clearance-free suspension and fixed adjustment, damage to the rotor tips and/or inside of the valve during (dis)assembly is limited to a minimum. In addition, the shaft seal cannot be damaged, since the spindle with spline remains in place when the rotor is pulled out.

In brief

- Suitable for frequent cleaning and inspection

- Self-seeking spline axis for quick (dis)assembly

- Absorbing differential pressure due to minimal air leakage

- Protective system up to 10 barg for products in dust class St1 and St2 (optional)

- Suitable for 24/7 industrial applications

- Differential pressure 1,5 barg

- ATEX 2014/34/EU certified (optional)

- Sanitary execution conforming to EHEDG guidelines for dairy and food industry (optional)

- CIP execution suitable for both wet as dry cleaning (optional)

Specifications

- Flange sizes: DN150 – DN350 (round)

- Flanges: drilled in accordance with PN10

- Rotor volume: 2,5 up to 58 ltr/rev

- Differential pressure: max. 1,5 barg

- Standard design temperature: 120 °C

- Flame proof: yes

- Explosion proof: up to 10 barg

Executions

- Extra spindle from size DG350 for safe, smooth (dis)assembly

- Sanitary execution for dairy and food industry

- Corrosion resistant execution for chemically aggressive products (3C/3N)

- Abrasion resistant execution for abrasive products (4C/4TCO)

- Specially coated execution for sticky products

- Customer-specific design