DTD plug diverter

- For diverting or converging of powders and granules

- Suitable for pneumatic conveying systems

- Clever, value engineered design

Introduction

The DTD dual channel plug diverter valves are made of aluminium LM25 grade through a high quality die casting process. All product contact surfaces are lined with 316 stainless steel tubes. The standard seals are FDA approved silicone, which ensures a complete sealing between the body and the plug.

The standard execution diverter with static seals can be used in pressure conveying systems where the pressure is less than 2 barg. When equipped with inflatable seals (optional), the DTD is suitable for systems up to 6 barg. The DTD is supplied as a complete unit with pneumatic actuator and associated components, such as solenoid valve, solenoid coils, junction box and position sensors.

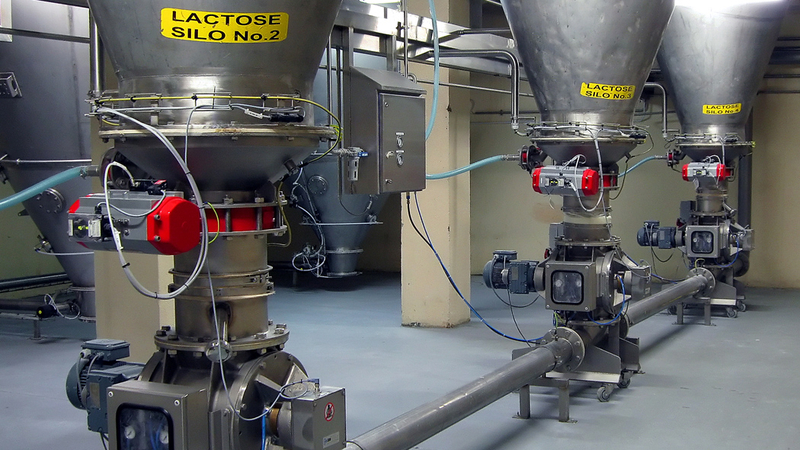

Applications

In brief

- Dual channel plug

- Suitable for powders, granules and pellets

- For diverting or converging

- Minimum product degradation

- Food grade silicone seals

- All product contact surfaces in stainless steel 316

- Aluminium body, plug and end covers

- No external moving parts

- Position indicators

- Air cylinder operated

- Easy maintenance

- Conforming to ATEX 2014/34/EU (optional)

Specifications & Options

Specifications

- Sizes (7) from 50 to 200 mm

- DIN / ANSI / JIS drilling patterns

- System pressure: up to 2 barg with static seals

- Standard design temperature: 80 °C (max)

Options

- Thicker stainless steel liner

- Wear resistant pipe liners

- High temperature version

- Dynamic (inflatable) seals up to 6 barg

- Polyurethane seals (static seal version only)