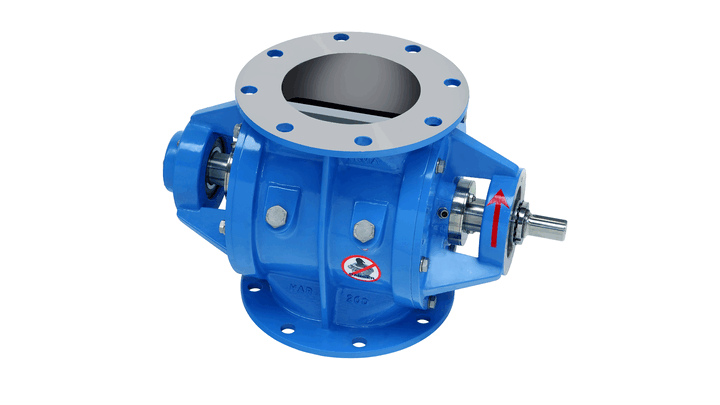

H-AR airlock

- High-duty drop through rotary valve

- 24/7 industrial applications

- Absorbing differential pressure

- Protective system up to 10 barg (St1 and St2)

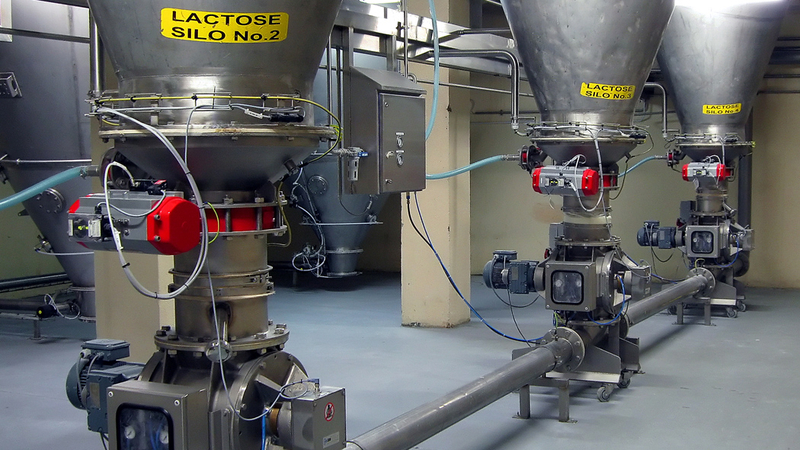

Introduction

TBMA high-duty H-AR drop-through rotary valves are used for dosing powder and granular materials in 24/7 industrial processes. The H-AR valves can be used as a protective system up to 10 barg for products in dust class St1 and St2.

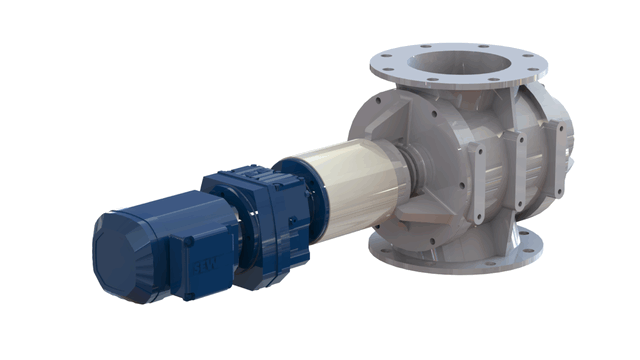

In combination with a blow-through or venturi adapter, the H-AR is very suitable for absorbing differential pressure in pneumatic conveying systems. The optimally constructed inlet of the valve ensures a high filling degree and large capacity with minimal air leakage.

Are you looking for a rotary valve? Use our Rotary Valve Specification Form as a guide to ask for a quotation and send it to sales@tbma.com. We will contact you asap.

Applications

In brief

- Dosing of powder and granular materials

- Absorbing differential pressure due to minimal air leakage

- Protective system up 10 barg for products in dust class St1 and St2 (optional)

- Suitable for 24/7 industrial applications

- Outboard bearings, dust tight and sealed for life

- Differential pressure 1,5 barg

- ATEX 2014/34/EU certified (optional)

- Sanitary execution conforming to EHEDG guidelines for dairy and food industry (optional)

Specifications

- Flange sizes: DN150 - DN500 (round)

- Flanges: drilled in accordance with PN10

- Rotor volume: 2,5 up to 125 ltr/rev

- Differential pressure: 1,5 barg

- Standard design temperature: 120 °C

- Flame proof: yes

- Explosion proof: up to 10 barg

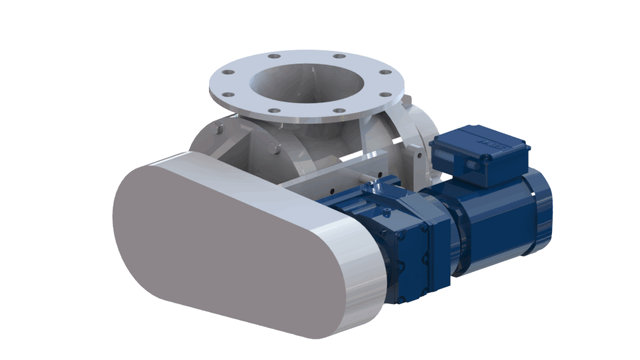

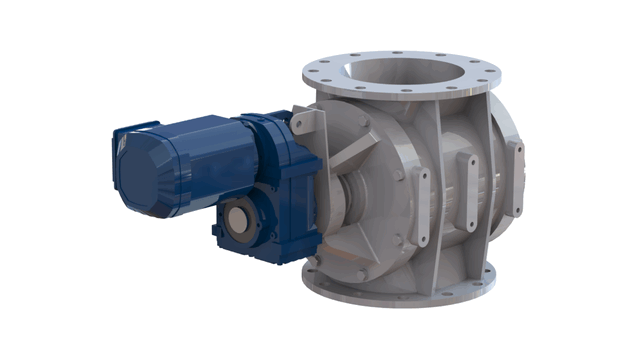

Executions

- Sanitary execution for dairy and food industry

- Easy detachable execution (D*)

- Easy detachable execution with guiding bars (Quick-Clean DG**)

- Corrosion resistant version for chemically aggressive products (3C/3N)

- Abrasion resistant version for abrasive products (4C/4TCO)

- Specially coated version for sticky products

- High temperature version up to 600 °C

- Customer-specific design

* Demountable | ** Demountable with Guiding bars