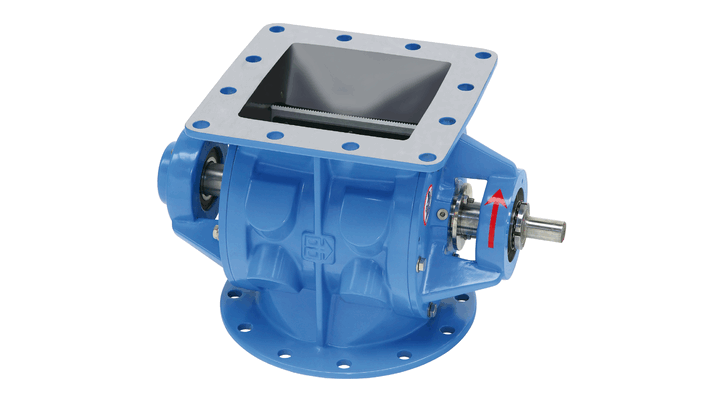

H-AX airlock

- High-duty drop through rotary valve

- Relatively large inlet for products with poor flowability

- Absorbing differential pressure

- Explosion proof up to 2 barg

Introduction

TBMA high-duty H-AX drop-through rotary valves are equal to the H-AR valves and are used when the inlet size is more important than the rotor volume. The relatively large inlet ensures that even the most poorly flowing products are efficiently discharged.

The H-AX valves are equipped with a round and a square connecting flange. This allows the valve to be used as a transition piece from round to square or vice versa. This is favourable for the installation height and saves any mounting parts.

Are you looking for a rotary valve? Use our Rotary Valve Specification Form as a guide to ask for a quotation and send it to sales@tbma.com. We will contact you asap.

Applications

In brief

- Dosing of powder and granular materials

- Absorbing differential pressure due to minimal air leakage

- Suitable for 24/7 industrial applications

- Relatively large inlet for products with poor flowability

- Outboard bearings, dust-tight and sealed for life

- Suitable as transition piece from round to square of vice versa

- Differential pressure 1,5 barg

- ATEX 2014/34/EU certified (optional)

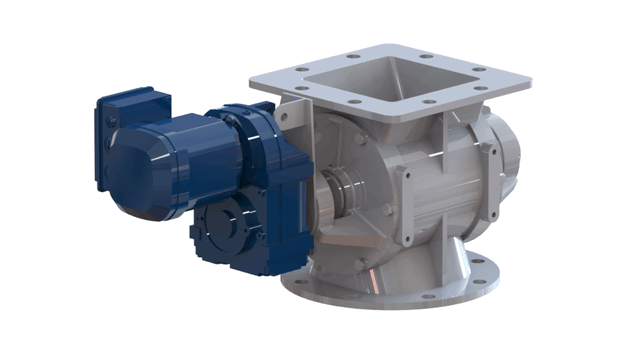

Specifications

- Flange sizes: DN150 – DN350 (round)

- Flanges: drilled in accordance with PN10 (round)

- Rotor volume: 2,5 up to 34 ltr/rev

- Differential pressure: 1,5 barg

- Standard design temperature: 120 °C

- Flame proof: yes

- Explosion proof: up to 2 barg

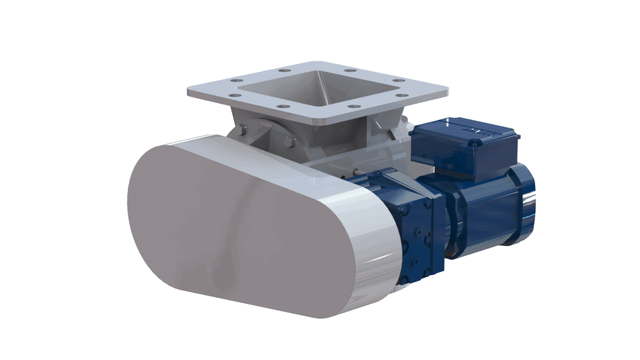

Executions

- Easy detachable execution (D*)

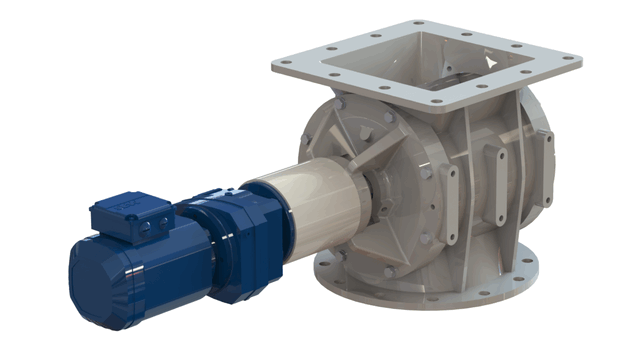

- Corrosion resistant version for chemically aggressive products (3C/3N)

- Abrasion resistant version for abrasive products (4C/4TCO)

- Specially coated version for sticky products

- High temperature version up to 600 °C

- Customer-specific design

* Demountable