PTS sampler

- Automatic sampler

- Suitable for pneumatic conveying systems

- Hygienic design

Pneumatic conveying lines

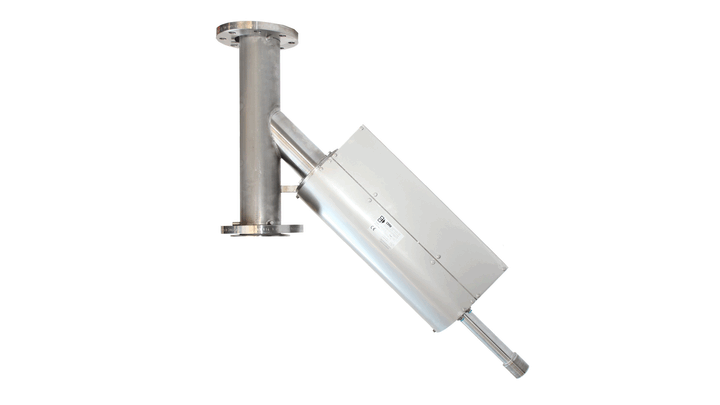

The PTS high-end automatic sampler can be used for sampling powders, granules or flakes out of vertical or horizontal pneumatic conveying lines.

It consists of a pipe section matching the diameter of the conveying line into which a stainless steel pipe is welded at a downward angle. This pipe holds a stainless steel 316 polished tube with bevelled and rounded end, ensuring that the end of the sampling tube does not interrupt the product flow when not in use.

Applications

Working principle

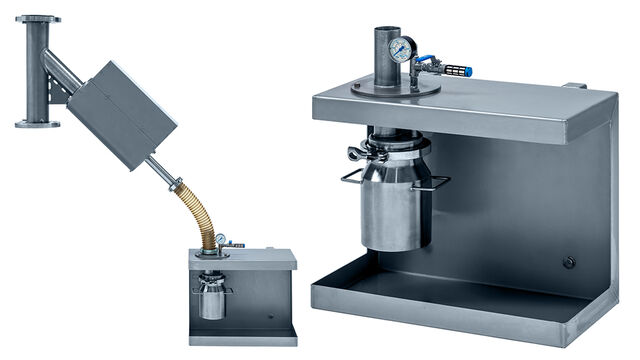

When starting the sampling cycle, the sampling tube is moved inside the product stream by means of a pneumatic cylinder. The product sample is taken from the line by an opening in the sampler tube.

The overpressure in the pneumatic transport system facilitates a smooth flow of the sample into the sampling jar, which is at ambient pressure. The sample jar holder is equipped with a pressure indicator and a manual valve with filter socket to depressurise the sampling system before disconnecting the sample jar.

PTS samplers can be supplied including a control unit, consisting of a cabinet with Siemens Logo PLC and fuses, switches, motor protector and frequency converter. The cabinet is internally wired and tested and standard suitable for a non-classified zone.

Features

- Suitable for powders, granules, and flakes

- Product contact parts food approved

Options

- Control unit

- Holder with sample jar (stainless steel)

- Niflon coating for sticky products