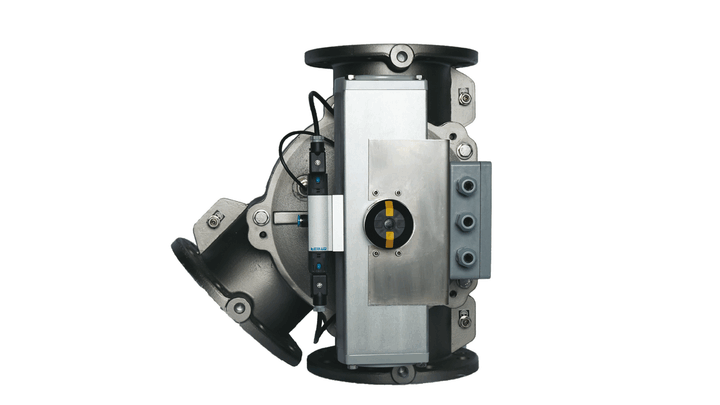

SDTD plug diverter

- For diverting or converging (optional) of powders and granules

- Suitable for pneumatic conveying systems

- Clever, value engineered design

Introduction

The SDTD single channel plug diverter valves are standard made of aluminium LM25 grade through a high quality die casting process. All product contact surfaces are lined with 316 stainless steel tubes. The standard seals are FDA approved silicone, which ensures a complete sealing between the body and the plug.

The standard execution diverter with static seals can be used in pressure conveying systems where the pressure is less than 1,5 barg. The SDTD can also be equipped with inflatable seals (optional) for higher system pressures. The SDTD is supplied as a complete unit with pneumatic actuator and associated components, such as solenoid valve, solenoid coils, junction box and position sensors.

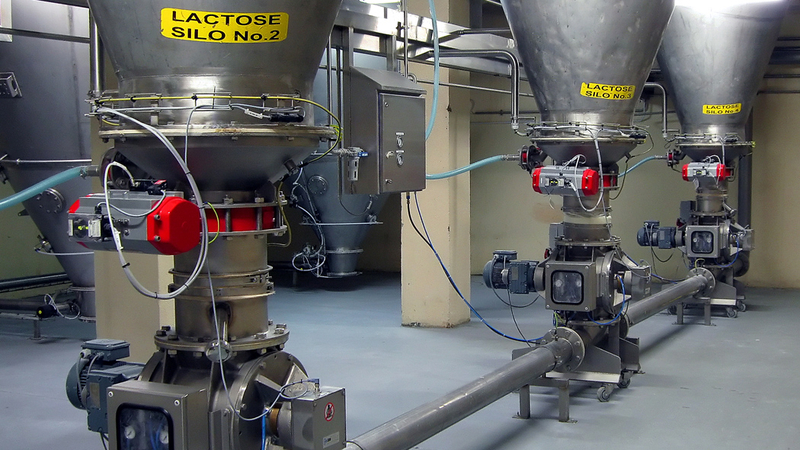

Applications

In brief

- Single channel plug

- Suitable for powders, granules and pellets

- Standard execution for diverting only

- Minimum product degradation

- Food grade silicone seals

- All product contact surfaces in stainless steel 316

- Aluminium body, plug and end covers

- No external moving parts

- Position indicators

- Pneumatic actuator operated

- Easy maintenance

- Conforming to ATEX 2014/34/EU (optional)

Specifications

- Sizes (4) from 150 to 300 mm

- DIN / ANSI / JIS drilling patterns

- System pressure: up to 1,5 barg with static seals

- Standard design temperature: 80 °C (max)

Options

- Thicker stainless steel liner

- Wear resistant pipe liners

- High temperature version

- Dynamic (inflatable) seals

- Completely stainless steel body and plug, allowing the diverter to be also used for converging (SDTD-C)

Let's converge!

The SDTD single pipe plug diverter is now also available for CONVERGING of powders and granules.

A major producer of polypropylene and polyethylene granules needed diverter valves for conveying 48 up to 80 tons/hr, depending on the conveying distance. They preferred to use the SDTD, due to its compact design. However, at some locations the diverters also needed to be able to converge to allow a line change in the event of a production line failure. A bit like train tracks, where trains can change tracks in either direction.

SDTD plug diverters are well known for their clever, value engineered design: the compact, single pipe design allows a large pipe diameter in relation to the size of the diverter. The standard SDTD version, however, is only suitable for diverting. It consists of an LM25 aluminium grade body and plug, lined with a 316 stainless steel tube, creating a rim at the inlet. This is no problem when diverting, but it would lead to product build-up when the diverter is used for converging.

Our solution was to provide the diverter valve with a completely stainless steel body and plug, so that there is no edge at either the inlet or outlet. As a result, this SDTD-C can be used for both diverting AND converging, while maintaining the engineering advantages of a diverter with relatively small installation dimensions compared to its pipe size.

A nice example of creating Solutions beyond Bulk Handling.

More info

Brochure Diverter Valves View