Food & Dairy

- Rotary valves and diverter valves

- Big-bag filling

- Big-bag discharging

- Bag emptying

- Pneumatic conveying

- Mixing and homogenising

- Sampling

- Silo storage and discharge

- Loading chutes

Hygiene and easy-cleaning

In hygienic production processes, it is of the utmost importance to prevent bacterial growth and product contamination and to guarantee traceability. At TBMA we work in accordance with the EHEDG, FDA and EC 1934/2005 guidelines, so that we can provide you with solutions aimed at maximum product safety. This is crucial for both the consumer and the protection of your brand.

When designing our sanitary components and systems, we ensure that they can be completely internally accessible and cleaned quickly. Our many years of experience with the storage, transport, dosing and processing of dry, powdered ingredients, such as milk powder, sugar, starch, cocoa, etc., means that we are allowed to work for internationally renowned clients.

Video: Feed your process

Components for the food and dairy industry: ROTARY VALVES | DIVERTER VALVES | SAMPLERS | LOADING CHUTES

Systems for the food and dairy industry: BIG-BAG FILLING | BIG-BAG DISCHARGING | BAG EMPTYING | PNEUMATIC CONVEYING | MIXING AND HOMOGENISING | SILO STORAGE AND DISCHARGE

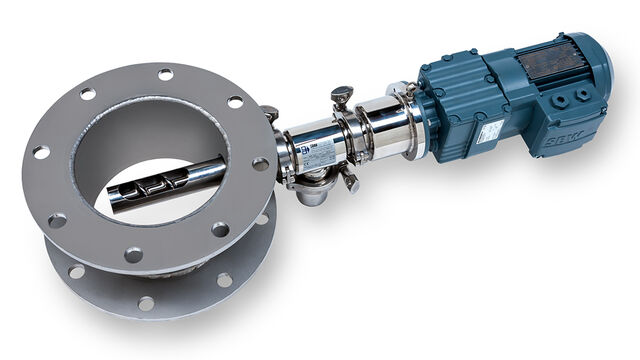

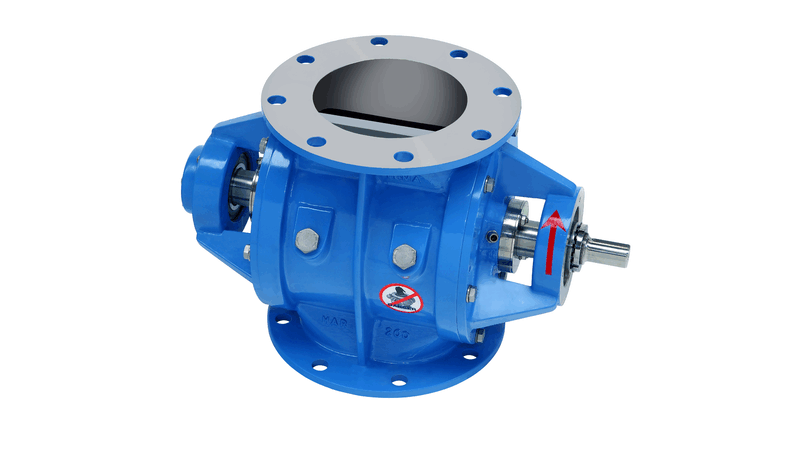

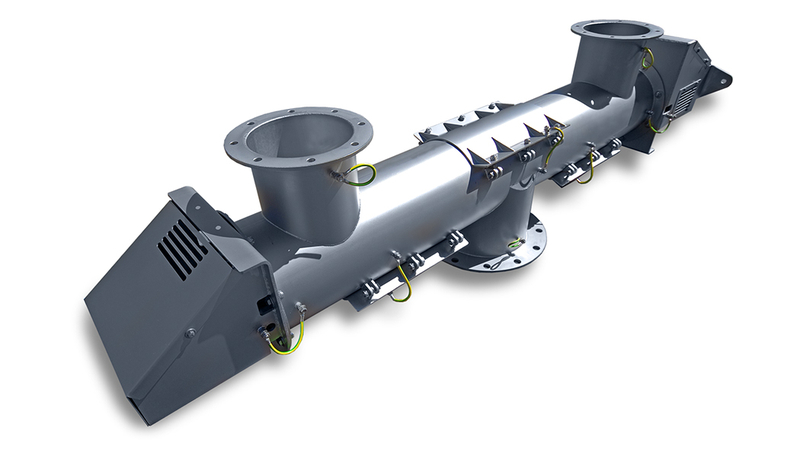

Rotary valves and diverters

H-AR/H-ARDG drop-through and H-GR/H-GRDG blow-through rotary valves are available in a sanitary execution, suitable for hygienic applications, e.g. dosing milk powder. The DG versions are Quick-Clean valves with guiding bars, specially designed for for processes where frequent cleaning and inspection are required. These valves are equipped with a self-seeking spline shaft, which means that after cleaning, the rotor can be quickly and easily mounted. Because of the clearance-free suspension and fixed adjustment, any metal contact of the rotor is practically impossible. Moreover, the change of damaging the rotor tips and/or the inside of the valve during (dis)assembly is limited to a minimum.

The TBMA H-series rotary valves are suitable for dosing powders and granules, absorbing differential pressure and as autonomous protection system up to 10 bar for products in dust class St1 and St2.

DTD plug diverters are very suitable for diverting or converging product flow in the dairy and food industry.

→ MORE INFO | QUICK-CLEAN ROTARY VALVES

→ MORE INFO | DIVERTER VALVES

Sampling

The quality of the end product is of the utmost importance in the food industry. Not only for public health, but also for possible claims. Producers must therefore be able to rely on representative product samples. TBMA offers a complete line of automatic samplers, applicable for different product types, production locations and processes.

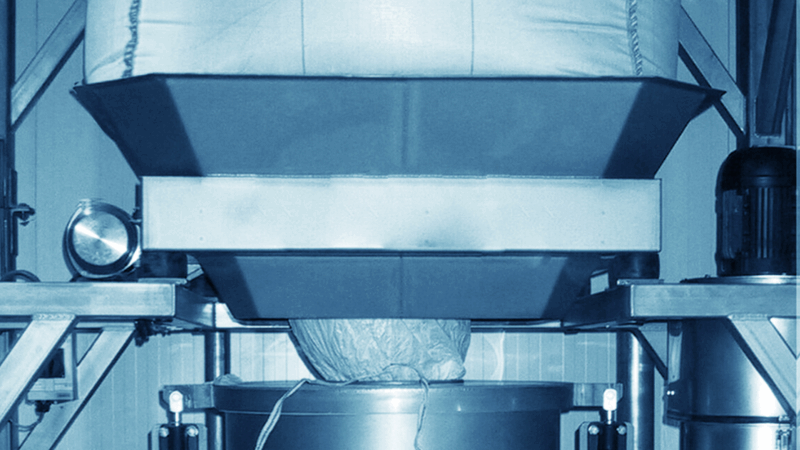

Big-bag filling

TBMA has the expertise and extensive experience with the engineering, installation and commissioning of sanitary big-bag installations, for example for the processing of baby milk powder. These big-bag or FIBC filling systems must work under strict hygienic conditions (clean room). Our hygienic big-bag filling lines guarantee a dust-proof, highly accurate and contamination-free transport of your product to well-filled, stable and straight, well-stackable big-bags.

When filled big-bags are stored for a longer period of time, the risk of product degradation occurs. For this, special gas-tight big-bags with an inner bag can be used, that are sealed airtight by the TBMA installation. The bag is then vacuumed by using a special valve in the big-bag and then injected with nitrogen. This way the shelf life of the product is considerably extended.

Big-bag discharging

TBMA big-bag unloading systems are specifically designed for trouble-free unloading of various products from different types of FIBCs. The liner clamping and clamping mechanism prevents dust, product loss and contamination.

The systems are suitable for processing single or multi-trip bags, with or without a plastic inner bag. A number of unique options have also been designed for the safe and hygienic release of food and pharmaceutical products.

The TBMA range is based on a clever and very flexible modular concept in which the basic models can be expanded with various options.

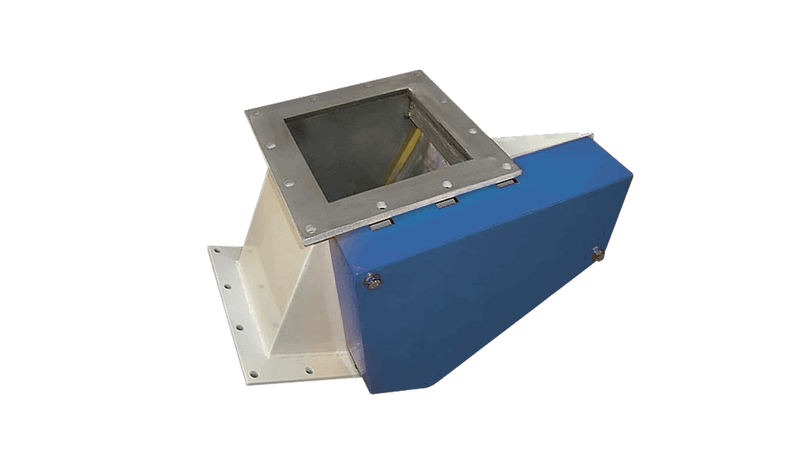

Bag emptying (25kg)

Many ingredients used in the food and dairy industry, such as sugar, milk powder, starch, cocoa, coffee and tea, are transported and supplied as bagged goods. The Galahad bag cutting and emptying system has been TBMA's optimum bulk transfer solution for cutting and emptying various types of bags from 25 up to 80 kg for more than four decades. The system is supplied as a semi-automatic or optionally fully automatic with a robot to place the bags on the conveyor belt.

The Galahad ensures continuous dust-free and hygienic emptying of the bags with a residual value between 0,01% and 0,05%. The bags are opened with one clean cut at which there is no contact between the outside of the bag and the product.

For smaller quantities, we supply various dust-proof bag dumping cabinets.

→ MORE INFO | GALAHAD BAG SLITTING AND EMPTYING MACHINE

→ MORE INFO | BAG DUMPING CABINETS

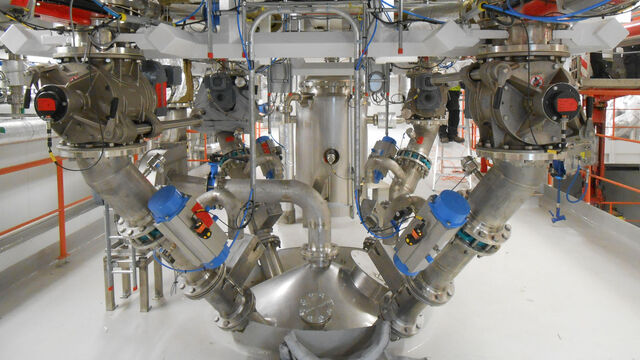

Pneumatic conveying

When it comes to pneumatic conveying in the food and dairy industry, we offer you both the components and systems as well as the knowledge and experience to select the best solution for you. Examples of products to be handled are milk powder, flour, sugar, potato starch and proteins.

We engineer and supply reliable and sustainable systems for dense phase and dilute phase applications. In the process we take into account the vulnerability, abrasiveness or segregation sensitivity of your products. When desired, we can deliver the system including control system.

Blending and homogenising

The VRM vertical blender by TBMA is very suitable for mixing larger batches of product and is often used for, for example, homogenising segregated batches.

The combination of a high degree of mixing and complete release makes the Conical Spiral Batch mixer very suitable for mixing for example proteins and vitamins in hygienic applications.

Silo storage and discharge

We work closely with renowned partners for the delivery of silos, blenders, tanks and hoppers designed by TBMA. This allows us to supply a full range of storage units in standard, vacuum or pressure applications and for the storage of various products. The silos etc are available in various materials and can be equipped with various peripheral equipment, such as level switches, valves, filters, explosion pannels, etc.

Loading chutes

Loading chutes are used for the dust-free loading of bulk goods in e.g. trucks. The Moduflex program with loading chutes has been completing our own product range for more than 20 years. This allows us to offer a total package of components and systems for the food industry.