Minerals

- Rotary valves and diverter valves

- Big-bag filling

- Big-bag discharging

- Bag emptying

- Pneumatic conveying

- Silo storage

- Loading chutes

Wear resistant and reliable

Minerals are frequently used raw materials in the manufacture of plastic, rubber, ceramic materials, paint or glass. The often abrasive properties of this type of product require a robust, wear resistant production facility.

TBMA has many years of knowledge and experience with systems for large volumes of for example, silica, quartz, cement or lime. High operational reliability and the prevention of production downtime are familiar challenges for us in this regard.

Components for the minerals industry: ROTARY VALVES | DIVERTER VALVES | LOADING CHUTES

Systems for the minerals industry: BIG-BAG FILLING | BIG-BAG DISCHARGING | BAG EMPTYING | PNEUMATIC CONVEYING | SILO STORAGE AND DISCHARGE

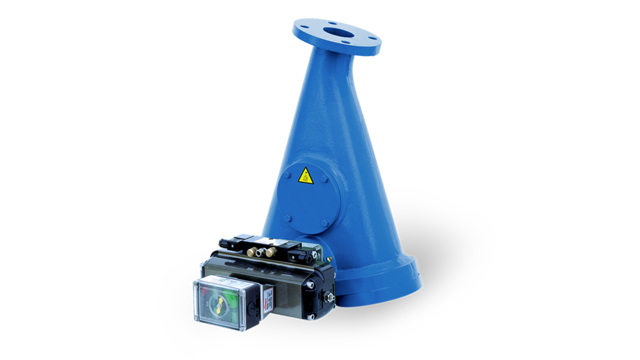

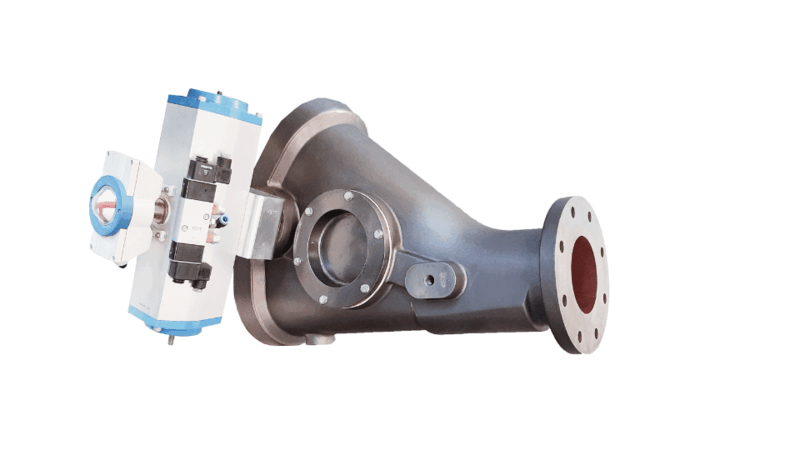

Rotary valves and diverter valves

Minerals are notorious for their abrasiveness. This means that rotary valves and diverters in particular must be able to withstand this as joints in the process. The TBMA H-series rotary valves can undergo a special hardening process for this and/or be provided with a Tungsten carbite wear-resistant coating. This increases the life time of the valves and prevents downtime.

These valves are suitable for dosing powders and granules, absorbing differential pressure and as autonomous protection system up to 10 bar for products in dust class St1 and St2.

Due to its robust design and construction of ductile cast iron, the BTD ball diverter is extremely suitable for diverting and converging abrasive products.

Big-bag filling

With TBMA big-bag filling and weighing systems big-bags are filled suspended, and optionally vibrated and weighed, regardless the type of bag. This ensures a stable, straight-filled bag that is easy to stack.

Due to the efficient filling and accurate weighing, our systems are used successfully in various types of mineral installations worldwide. Product loss and formation during filling are thus prevented, which is certainly of great importance with highly aerating fine products such as talcum powder.

Our modular big-bag filling systems are available for processing bags with a filled weight of 500 up to 1.600 kg. Depending on the product supply and system layout, a filling capacity of 20 bags per hour can be achieved.

Big-bag discharging

TBMA big-bag unloading systems are specifically designed for trouble-free unloading of various products from different types of FIBCs. The liner clamping and clamping mechanism prevents dust, product loss and contamination.

The TBMA range is based on a clever and very flexible modular concept in which the basic models can be expanded with various options.

TBMA has developed a dustproof multi-purpose big-bag discharge and dosing unit for the cement industry, with which the basic product is discharged from a big-bag, coupled to a ‘master-slave’ continuous dosing system for additives. The installation has special features for poorly running minerals such as TiO2.

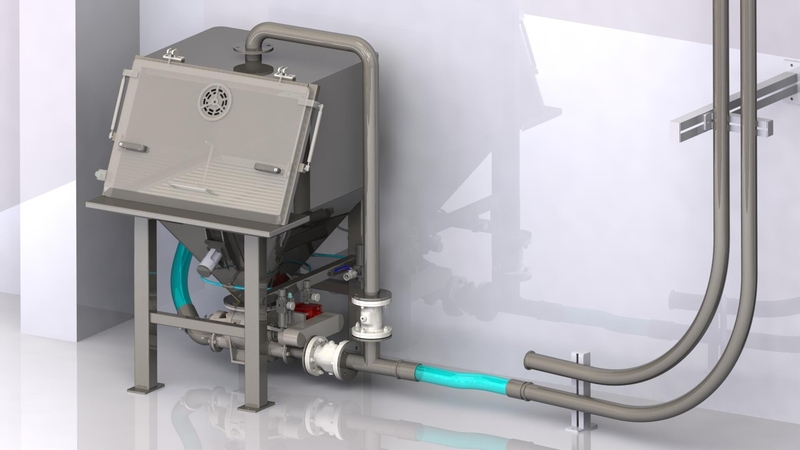

Bag emptying

Many minerals, such as cement, titanium dioxide and calcium carbonate, are transported and supplied as bagged goods. The Galahad automatic bag emptying machine has been TBMA's optimum bulk transfer solution for cutting and emptying various types of bags from 25 up to 80 kg for more than four decades. The system is supplied as a semi-automatic or optionally fully automatic with a robot to place the bags on the conveyor belt.

The Galahad ensures continuous dust-free emptying of the bags with a residual value between 0.01% and 0.05%. The system can directly fill a bulk truck and big-bags or be connected to a pneumatic or mechanical transport system.

For smaller quantities, we supply various dust-proof bag dumping cabinets.

→ MORE INFO | GALAHAD BAG SITTING AND EMPTYING MACHINE

→ MORE INFO | BAG DUMPING CABINETS

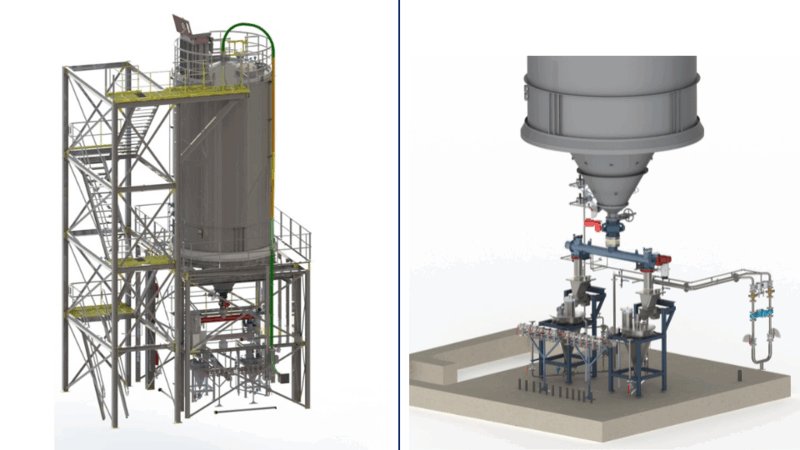

Pneumatic conveying

When it comes to pneumatic conveying, we offer you both the components and systems as well as the knowledge and experience to select the best solution for your production process. TBMA uses high-pressure, low-speed transport for wear-resistant products. In addition, we limit the number of moving product contact parts to a minimum so that excessive wear, capacity loss or outright leakage is prevented.

We engineer and deliver continuous and charge (plugflow) transport systems, also for large distances, both in a ‘point-to-point’ and ‘point-to-multipoint’ version. When desired, we can supply the system including control system.

Silo storage

We work closely with renowned partners for the delivery of silos, blenders, tanks and hoppers designed by TBMA. This allows us to supply a full range of storage units in standard, vacuum or pressure applications and for the storage of various products. The silos etc are available in various materials and can be equipped with various peripheral equipment, such as level switches, valves, filters, explosion pannels, etc.

→ MORE INFO | SILO STORAGE AND DISCHARGING EQUIPMENT

Loading chutes

Loading chutes are used for the dust-free loading of bulk goods in e.g. trucks. The Moduflex program with loading chutes has been completing our own product range for more than 20 years. This allows us to offer a total package of components and systems for the mineral industry.