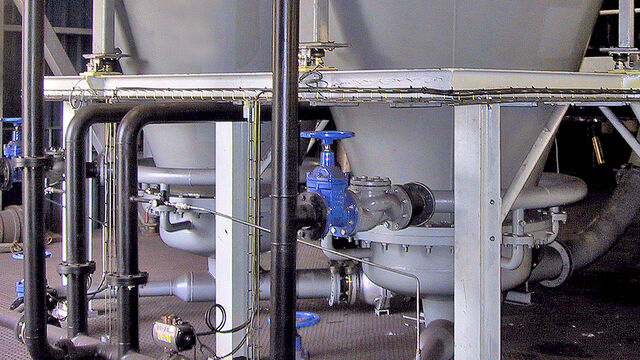

Dense phase conveying

Dense phase (high-pressure) pneumatic conveying systems are especially suitable for processing abrasive and sensitive products or for bridging large distances.

High pressure - low conveying speed

With this type of pneumatic conveying installations there is generally a high pressure in combination with a low transport speed to transport the product. In contrast to low-pressure systems, one does not use a rotary valve to feed the product into the transport line.

For high pressure pneumatic conveying systems we use our in-house designed pressure vessels with a pulsator (Pneuconveyor) to feed the product directly into the transport line. The Pneuconveyor has a minimal number of moving parts, making this type much less sensitive to wear and transport gas leakage.

The Contiveyor, also developed in-house, is highly suitable for continuous high-pressure transport.

TBMA high pressure transport systems are available in various capacities with transport lengths of up to 1.000 meters.

Characteristics

- Suitable for abrasive and fragile products

- High pressure | Low conveying speed

- Conveying pressure up to 6 bar

- Conveying speed 2 - 10 m/s

- Batch or continuous conveying

- Minimum product damage

- Less wear on transport lines

- Conveying distances up to 1.000 meter

Our specialty

TBMA can offer you excellent solutions for high-pressure, low-pressure and vacuum conveying systems. Our pneumatic conveying systems can also be supplied in a ‘closed-loop’ version, whereby transport gases (such as nitrogen) are continuously reused.

You can find a number of our completed projects on this website in Projects.

Interested in more information or do you have a request for a specific project? Please contact us at sales@tbma.com or call +31 252 375068.