Galahad

The Galahad bag slitting and emptying machine is the optimal solution for easy repackaging of powders and granules from bags to big-bags or Octabins and transfer of bagged goods to bulk trucks or bulk storage.

Proven solution

Being used for more than four decades, the Galahad is a proven solution for slitting and emptying various types of bags from 25 to 80 kg. TBMA offers several executions for handling almost all single and multi-layered bags: paper, plastic, woven polyethylene or hessian, small or large and light or heavy in weight. Products handled include PVC powder and granules, sugar, flour, starch, coffee and cocoa beans, titanium dioxide, cement, etc.

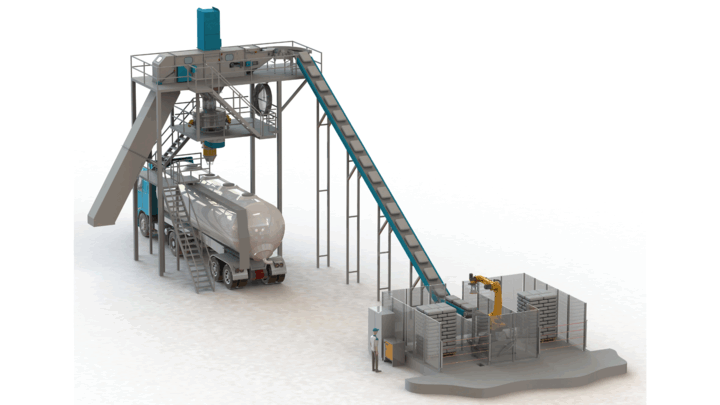

The Galahad is the optimal solution for easy repackaging of powders and granules from bags to big-bags or Octabins and transfer of bagged goods to bulk trucks or bulk storage. This automatic, labour-saving bag slitting and emptying machine is suitable for use in the food, animal feed, chemicals and minerals industries. Especially for the Value Added Logistics (VAL) sector, the Galahad is a valuable, indispensable asset.

Applications

Safe, dust-free and hygienic

The Galahad ensures continuous safe, dust-free and hygienic emptying of bags with a residual value between 0,01% and 0,05%. The bags are opened with one clean cut with no contact between the outside of the bag and the product, ensuring there is no product contamination. The system can directly fill a bulk truck or big-bags or be connected to a pneumatic or mechanical conveying system. Due to the smart construction and the high speed, a capacity can be achieved up to 1500 bags or 40 tons per hour, depending on the type of product, the bag size and the level of automation.

Different levels of bag feed automation are available: basic, semi-automatic or full-automatic. The full-automatic execution can be equipped with a single-head or multi-head robot for full-automatic feeding.

Robotisation

When using a robot, either single-head or multi-head, the complete system can be operated by a single person. This labour-saving solution for emptying bags ensures a very favourable ROI.

The operator places the pallet with bags in the designated spot, so the robot can pick up the bags. To fully use the robot’s potential and thus creating continuous bag supply, two or more pallet spaces must be available within reach of the robot. This way the operator can change the empty pallet for a full one, while the robot continues with the next pallet.