TBM turbo mixer

The TBM turbo mixer has been developed for mixing and dispersing powders in liquids, with high demands on product fineness, good product wetting and relatively low energy consumption.

High-quality dispersion

The height-adjustable mixing disc combined with the scraper blade construction is ideally suited for dispersing temperature-sensitive products, such as PVC components and color pigments in paint. Viscous liquids up to 25.000 cP with a solids content up to around 80 % can be processed excellently in this mixer. The TBM is designed and manufactured according to the PED guidelines for full vacuum and overpressures up to 6 bar.

The TBM turbo mixer is equipped as standard with a static high-speed mixing disc with a fixed diameter and a slow-rotating mixer/scraper for secondary mixing. This combination gives an optimal mixing result with low energy consumption. The scraper also prevents the product from growing on the mixer wall.

Characteristics

- Closed system, suitable for overpressure and vacuum

- Relatively low installed power

- Automatic height adjustment for optimum dispersing position

- Conical version for small batches

- Optional cooling and heating

- High dispersing efficiency

- Minimum dispersing time

- Capacity from 500 to 10.000 liters

Executions

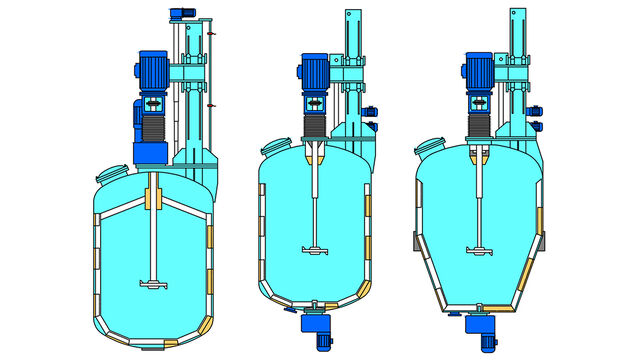

The TBM turbo mixer is available in three versions (from left to right):

- Type TBM-ST-R: top-driven, height-adjustable central mixing disc | mixer/scraper above drive

- Type TBM-SB-R: mixing disc above drive | mixing scraper beneath drive | automatic height adjustment

- Type TBM-C-R: conical mixing vessel | top driven mixing disc | mixer/scraper beneath drive| automatic height adjustment

The mixer can be optionally equipped with a height-adjustable mixing element. This height adjustment is also available with PLC control, which seeks the optimum mixing position based on the power consumption. The combined working of the primary mixing element, mixer/scraper and height adjustment ensure a very high dispersion.